Full automatic greenhouse roof washer

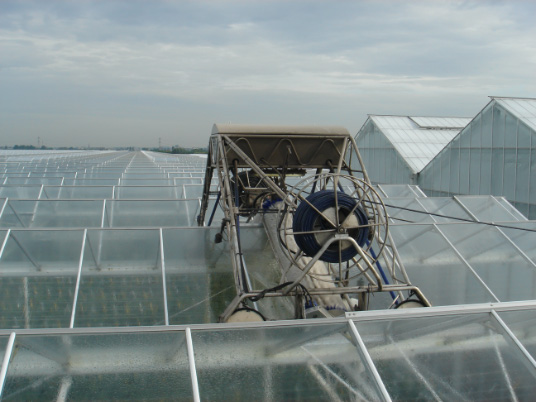

The full automatic Roofmaster is, as the name suggests, fully automatically operated by the greenhouse’s climate computer. After the release signal, the wash program starts automatically. If the release signal is lost, the Roofmaster finishes its wash cycle on the roof. This consists of a return trip. The roof washer always returns to the platform and waits for the next release signal.

Air vents close automatically

The advantage of the fully automatic version is that the air vents of a department close automatically when the roof washer starts to wash this department. The skylights of the other departments can then simply remain open. The manual and semi-automatic version do not have this function. In the event the skylights open unexpectedly? Then the skylight detectors ensure that the Roofmaster stops on time.

From smartphone

Just like the semi-automatic version, the fully automatic Roofmaster has a touchscreen. Settings such as the start and end time or the number of rows to be washed are clearly displayed and easily adjusted. You can also operate the operating system with a handy app on your smartphone or tablet. With this remote access function you always have control at hand. You do not have to be present at the Roofmaster itself.

Customization

Growers grow different crops, have different greenhouses and all have different wishes when it comes to greenhouse roof washing. For this reason every Roofmaster we build is different. Since we develop all components in-house, even the most challenging customization is no problem for us. Every Roofmaster including displacement platform and accessories is tailor-made, installed on site and adjusted. Everywhere in the world.

Favorable delivery time, excellent service

Because have the full production process in-house we are not dependent on specific suppliers. As a result, we are able to link favorable delivery times to excellent service. Do you have a question or is there a malfunction? Then it is important to offer a solution as quickly as possible. Since we have developed every component of the Roofmaster ourselves, we have all the knowledge in-house.

Options fully automatic greenhouse cover washer

Click on an option for more info.

Washing

-

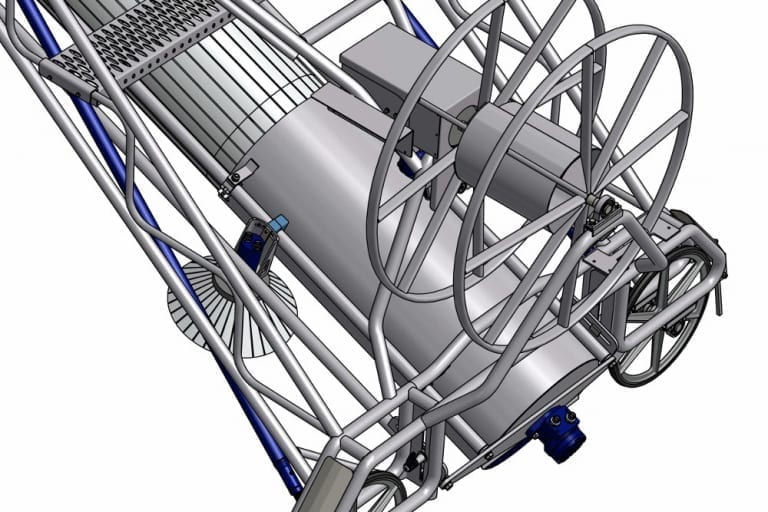

Water pump truck

The high-pressure pump truck has a capacity of 37 liters per minute and 55 bar, and the spray truck a buffer tank of 200 liters. The rear of the spray trolley can be equipped with manually operated hose and cable reels.

-

Air window detection

With four switches, the air window detection system ensures that the roof washer stops as soon as the machine runs against an open air window. A window that is only slightly open is recognized by the switches.

-

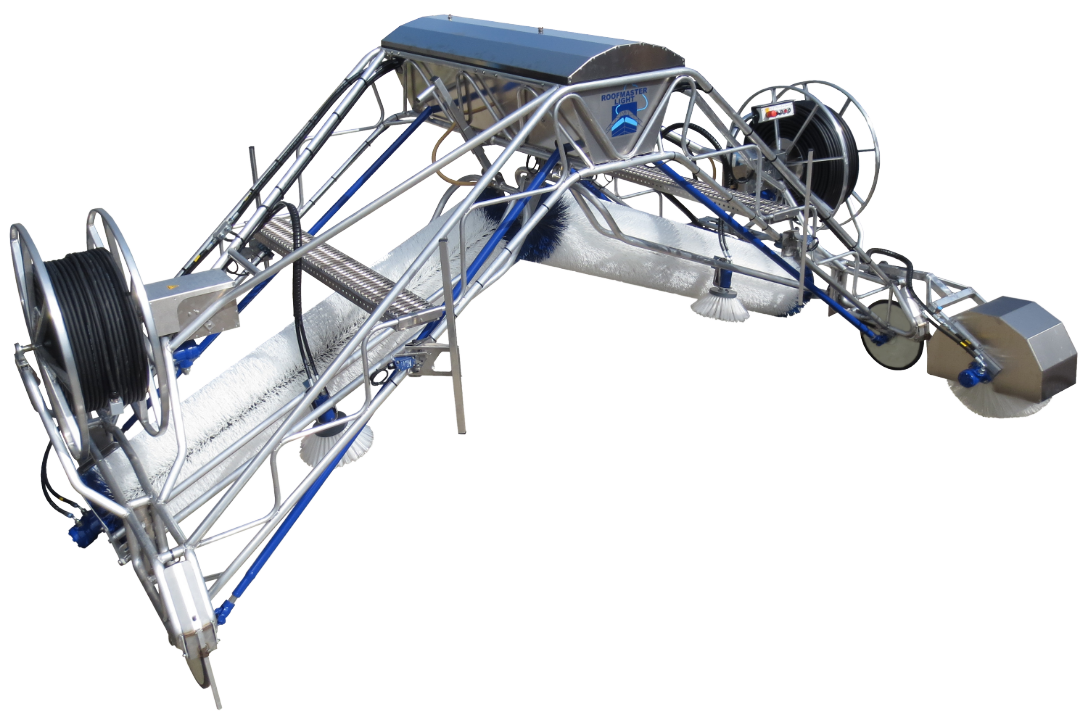

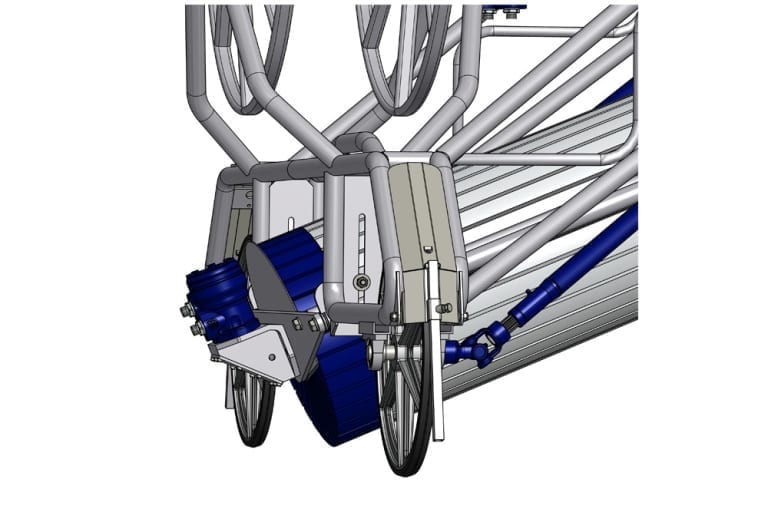

Cup brushes

The cup brush cleans the lower edge of the air vents. The brush can be moved, so that also the gutter edge and lower parts of the greenhouse cover are reached.

-

Gutter brush

The gutter brush with adjustable rotation speed prevents blockage and ensures that the gutters are thoroughly washed. There is also a wide version available for shallow gutters. In addition to the gutters, this wider brush also thoroughly cleans the lower parts of the greenhouse roof.

-

Brush covers

There are brush covers on all main brushes. These stop splashing dirt and water, so that the hood next to it stays clean. They also protect the brushes from the sun, which extends the life time.

-

Brush height adjustment

The height of the brushes is easy to adjust. This option makes the roof washer suitable for several different greenhouse roofs.

-

Angle brush drive

The angled brush drive provides the brush motor with an angled gearbox. This creates extra space between the roof washer and the greenhouse roof. This option is used for dilatations.

-

Gutter sprayer

This high-pressure cleaner sprays all the dirt away from places where the gutter brush can not reach easily.

-

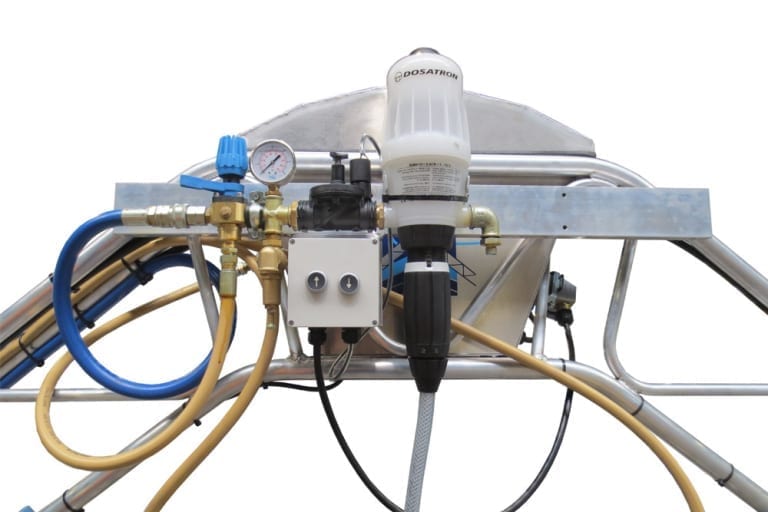

Dosatron dosing pump

The Dosatron dosing pump makes it possible to add solvents to the water. For example, applied coatings and screening agents can be washed off the greenhouse roof.

-

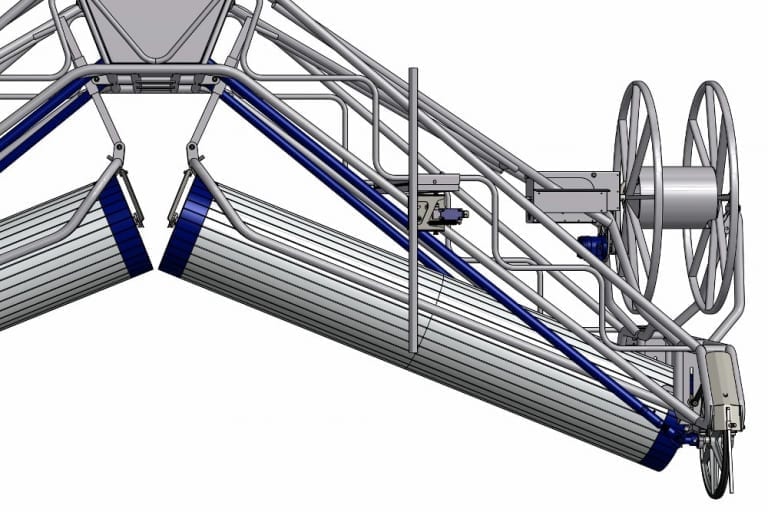

Cable and hose guide

Conductors for the reels ensuring even winding and unrolling of the electrical cable and water hose. This way cable and hose last longer.

Platform

-

Custom platform

A customized implementation of the platform is desirable in some situations. The platform is then specially designed and manufactured for this situation.

-

Reel set

The maximum length over which the platform can drag the power cable and water hose is approximately 100 meters. You can extend the maximum distance with a reel set. This is useful for longer facades, in addition, a reel set also offers a solution for uneven or rough terrain.

-

Standard platform

This is the most common version of the platform, also seen as a fixed setup. Generally speaking, this platform will hangs its entire life span on the facade of the same greenhouse. A well-thought-out design guarantees that the platform can be reached safely. It is equipped with a handrail and can be reached via a cage ladder.

Control

-

Remote access

Washing the greenhouse roof remotely: it’s possible with our remote access. With this handy app you can move the control screen from the roof washer to your smartphone or tablet. This way you can also operate the roof washer if you happen to be just on the other side of the site. Or even from another growing location or from home.

Spray coatings

-

Spray trailer with two blending tanks

The spray pump membrane pump has a capacity of 60 liters per minute and 40 bar. The trailer is equipped with two tanks of 1,000 liters each. Both tanks have a stirrer and injector to mix the mixture. The advantage of two tanks is that a new mixture is produced during spraying. The rear of the trailer can be equipped with a hose and cable reel.

-

Spray truck with two blending tanks

The spray pump diaphragm pump has a capacity of 60 liters per minute and 40 bar. The spray truck is equipped with two 500-liter tanks, both of which have a stirrer mixer and injector to mix the mixture. The advantage of two tanks is that a new mixture is produced during spraying. The rear of the spray trolley can be equipped with a hose and cable reel.

-

Spray truck with blending tank

The spray pump diaphragm pump has a capacity of 60 liters per minute and 40 bar. In addition, the tank has an injector to mix the spray mixture. The spray trolley is available in multiple versions: with a 600-, 1.000-, 1.500- and even 2.000-liter tank. The rear of the spray trolley can be equipped with manually operated hose and cable reels.

-

Push button box

With the removable push button box, the roof washer and the loading and unloading legs can be operated manually. You can also move the platform manually with it.

-

Operating platform

A safer way to drive along with the roof washer. The operating platform is equipped with a control panel.

-

Spray booms

Ideal for greenhouse growers who not only wash the greenhouse roof, but also wish to apply coatings: the roof washer will be equipped with foldable spray booms that can spray screening agents and coatings to the greenhouse. They can spray three peaks at once: one and a half going towards the end, and one a half on the way back. This is done at a higher speed than washing, to ensure a high quality of works and to limit the closing of vents to a minimum of time.

The spray booms are operated with the valves on the operating platform, where a button box is positioned as well.

Safety

-

Roof slide

The roof slide makes it possible to move through the gutters more safely. This is possible both standing and sitting. The skis on the side are adjustable in width. This makes the cover slide suitable for any greenhouse.

-

Set of protective equipment

At Besseling Techniek we are convinced of the importance of working safely. That is why we have put together a set of protective equipment with a harness, helmet and safety line. These can be used in addition to the standard security interventions, such as the handrail and cage ladder.